XZ6600 XCMG Trenchless Horizontal Directional Drill Rig Machine HDD Drill Machine

Enquiry Now!XZ6600 XCMG Trenchless Horizontal Directional Drill Rig Machine HDD Drill Machine

Model:XZ6600 horizontal directional drilling machine

Producer: Group

XZ6600 horizontal directional drilling machine is one-piece and full-drive drilling machine, which adopt the electro-hydraulic proportional control and load sensitive control and a number of advanced control technology and the company’s proprietary technology. The main performance parameters and control technology has reached the international advanced level. The main components choose the international brand-name products with the high reliability.

1. The highlights

1.The machine adopts the load sensitive control and electrohydraulic proportional control and other several advanced control technology. The imported components have the reliable quality.

2.The gear and rack push and pull to ensure the stability and the reliability of the transmission of power head operation.Power head’s floating can greatly protect the drill pipe thread and improve the service life of the drill pipe.

3. The Volvo high-power engine system is powerful. The huge power reservecan meet the construction of the horizontal directional drilling machine under the different working conditions.

4.The sliding of the drilling machine relies on the push and pull action of the cylinder.The adjustment of the grave angle is simple, convenient and safe.

5. There are the floating vise. There are the big torque and reliable clamping.

2. The introduction of the technology

2.1 Chassis

XZ6600 adopts the steel tracks with the strong adaptability and the high reliability. The import walking speed reducer has the stable and reliable performance.

| Track length | 4930 mm |

| Track outerwidth | 3050 mm |

| Track width | 600 mm |

| Wheelbase | 4027m |

| Number of the roller | 9piece*2 |

| Walking reducer | GFT60T3×2 |

| Driving force | 333kN |

| Gradability | 30% |

| Walking speed | 0.9km/h |

| Ground pressure | 110kPa |

| The total quality of work | 58t |

2.2 Engine

Power station: choosing Volvo turbo engine, which is powerful and meets China’s three stage emission standards.

| Type | TAD1643VE |

| Rated power | 565kW/(1850r/min) ×2 |

| Max. torque | 3287 N·m /(1200r/min) |

| Emission standard | Third stage |

| Fuel tank volume | 1950L |

Host: choosing Dongfeng cummins engine, which is powerful and meets China’s second stage emission standards.

| Type | 6BTAA5.9-C180 |

| Rated power | 132kW/(2200r/min) |

| Max. torque | 770 N·m /(1500r/min) |

| Emission standard | Second stage |

| Fuel tank volume | 170L |

2.3 Hydraulic system

Rotation uses the open loop. Other functions use the load sensitive control and electrohydraulic proportional control and several advanced control technology. The imported components are reliable in quality.Equipped with manual operation system, it can help to deal with special circumstances and protect the safety of construction.

| Power head rotation system | |

| Rotating pump | Rexroth A11L ×3/2/1 |

| Rate of flow | 520L/min |

| Pressure | 320bar |

| Motor | Rexroth A6VM ×6 |

| Power head push and pull system | |

| Pump | Rexroth A11 ×3/2/1 |

| Rate of flow | 520L/min |

| Pressure | 320bar |

| Motor Rexroth | A6V ×8 |

| Push and pull valve | AMCA PR-3211-B05 |

| Power station | |

| Hydraulic volume | 2050L |

| Host hydraulic volume | 210L |

2.4 Electrical system

Equipped with electric starter button, fuse box, power master switch.

In view of the technology of the horizontal directional drilling construction, the application of advanced control technology, which optimize the display position in the instrument.Using the large instrument is easy to observe.Walking-wire control can realize stepless speed regulation. It is convenient to operate.Engine speed, water temperature, oil pressure, hydraulic oil temperature, oil filter, power head limit and other alarm parameters can be monitored and effectively protect the security of the machine.

| System voltage | DC24V |

| Rotation handle | Sauer MCH22 |

Identity of welded drill with standard pipe bracket is convenient to operate. Drill sliding is driven by oil cylinder. It is convenient to adjust.

| Distance of the drill sliding | 2500 mm |

| Adjusting angle | 8~16° |

2.6 Power head

The horizontal directional drilling machine is push and pull by the gear rack and complete; Power head floating mandrel device effectively protect drill pipe thread; Variable motor to achieve high-speed push-pull; Push pull size can be adjusted according to the requirements of the construction of inorganic, protection of drill pipe.

| Max. push and pull force | 6600kN |

| Max. push and pull speed | 28m/min |

| Max. rotating torque | 160000N·m |

| Max. Rotating speed | 90r/min |

| Max.distance | 10500mm |

| Rotating speed reducer | Bonfiglioli 309 L2 |

| Push-pull reducer | Bonfiglioli 315 L3 |

2.7 Vice

Horizontal directional drilling machine is equipped with powerful shackle vice, which can move in the drill on the whole. The front and rear vice can relatively slip, which is convenient to maintenance and replace the saber tooth.

| Shackle torque | 337800N·m |

| Rear vice rotation Angle | 22° |

| Vice separation distance | 300mm |

2.8 Lorry crane

Random configuration is the 5 t lorry crane. The manual operation is stable and convenient.

| Max. lifting weight | 5t |

| Max. working range | 8.5m |

| Max. lifting moment | 12.5t·m |

2.9 Independent operating room (optional)

Equipping with the independent operation of air conditioning room, which is away from the vibration and noise. The independent operation room is comfortable. The horizontal directing drilling machine cann’t be installed with the cabin.

| Input power | 220V |

| Dimension( L*W*H mm) | 3500X2438X2591 |

| Air conditioning power | 1.5P |

2.10 Drill and pipe(option)

The customer can choose standard oil drill pipe or special double top type trenchless pipe. The expansion implement can choose cut-expansion type, expanding type, port type or other special reamer, whose diameter is from 300 mm to 1200 mm. The customer can also choose the specific products according to your own needs matching other types and specifications of the short connection and transfer, etc.

Note: the biggest hole diameter and the construction of the longest distance is associated with specific construction formation.

| Drill pipe diameter | φ194mm |

| Drill pipe length | 9600mm |

| Drill pipe joint size | 6-5/8FH |

3. The main technical parameters

| Item | Unit | Numbers | |

| Power station: engine | Manufacturer | Volvo | |

| Type | TAD1643VE | ||

| Rated power | kW/ rpm | 565×2/1850 | |

| Host:engine | Manufacturer | Dongfen Cummins | |

| Type | 6BTAA5.9-C180 | ||

| Rated power | kW/ rpm | 132/2200 | |

| Push and pull | Type | Eight motor drive gear and rack type | |

| Biggest drag/ feeding force | kN | 6600/6600 | |

| Power head speed | m/min | 0~28 | |

| Rotation | Type | Sixmotor drive gear transmission | |

| Max. torque | N.m | 160000 | |

| Speed | r/min | 0~90 | |

| Diameter | mm | φ194 | |

| Length( Single) | m | 9.6 | |

| Drill stand | Type | Sliding box drill stand with the bedplate | |

| Adjusting angle | ° | 8~16 | |

| Lorry-mounted crane | Type | Rotary arm straight telescopic crane | |

| Max. lifting quality | t | 5 | |

| Walking drive | Type | Steel crawler self-propelled | |

| Walking speed | km/h | 0.9 | |

| Gradeability | % | 30 | |

| Slurry pump | Type | Independent pump station (external) | |

| Flow | L/min | 2500 | |

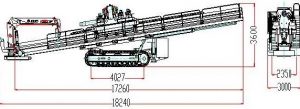

| Host dimension | mm | 18240*3000 *3600 | |

| Power station dimension | mm | 7500*2300*2400 | |

| Operating room dimension (Option) | mm | 3500*2438*2591mm | |

| Host weight | t | 58 | |

4. Configuration of main components

| Engine( Power station) | Volvo |

| Engine(Host) | Dongfeng cummins |

| Main pump | Rexroth |

| Rotation motor | Rexroth |

| Push and pull motor | Rexroth |

| Rotation reducer | Bonfiglioli |

| Push and pull reducer | Bonfiglioli |

| Main valve | AMCA |

| Hand shank | SAUER |

| caterpillar | Xianning, Hubei province |

| Walking reducer | Rexroth |

| Lorry-mounted crane | |

| Hose connection |

5. The appearance and transportation of the machine

| Host dimension(L*W*H mm) | 18240*3000*3600 |

| Host shipping weight | 58t(Do not include the drill pipe and drill) |

| Power station shipping weight | 16t |

| Operating room shipping weight | 2t |

6. Transport scheme

In order to meet the requirements of highway transportation, the host is divided into two parts to transport. There is engine, hangar, rocker arm, fuel tank, hydraulic oil tank, carriage, rocker arm and other parts in the below position.. The drill body, power head, vice, anchor, lorry crane and others in the upper position.

| The upper parts dimension(L*W*H mm) | 18240*3000*2720 |

| Weight | 41T |

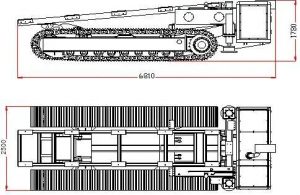

| The below parts dimension(L*W*H mm) | 6810*2500*1780 |

| Weight | 17T |

7. The documents

XZ6600 horizontal directional drilling machine is accompanied by the following technical documents:

Product certificate

Product specification

The engine maintenance manual

Reducer operation instruction

Slurry pump maintenance manual (option)

Packing list (Including wearing parts and spare parts list, the accessory tools list)