XZ320D Horizontal Directional Drill

Enquiry Now!Model: XZ320D Horizontal Directional Drilling Equipment

Manufacturer: XCMG

XZ320D horizontal directional drilling equipment possess compact, high performance, full-featured features. It takes the gear rack pushing&pulling. Its main performance parameters and control technology has reached the international advanced level. Its hydraulic system, power system, walking system and other major components are selected international first-class brands, with good performance, good reliability advantages.

ONE. highlights introduction

1.XZ320D horizontal directional drilling equipment has strong power. It uses 153kW high-power EUROIII emission standard engine. This engine power strong enough to ensure that rigs in a variety of complex geological conditions to complete the pipe laying operations;

2.XZ320D horizontal directional drilling equipment using the rack and pinion push-pull approach. This design to ensure the stability of the power head and drive the reliability of the transmission;

3.XZ320D horizontal directional drilling equipment power head and vice being double floating patented technology can greatly protect the drill pipe thread, improve the service life of drill pipe;

4, hydraulic system optimization design to achieve the power head rotation, push-pull two-speed control, and increase the adaptability of drilling conditions to enhance the efficiency of drilling rig;

5, Support customer demanding diversification, the machine can be equipped with automatic (semi-automatic) drill pipe loading system, automatic anchoring device, cabin, air conditioning, cold start, mud antifreeze, mud cleaning,mud saving ects

TWO Technical Introduction

1, the engine system

XZ320D horizontal directional drilling equipment adopts Cummins engineering machinery dedicated turbocharged engine. It is powerful, energy-saving and efficient, can meet the national phase II emission standards;

Engine model 6BTAA5.9-C205

Rated power 153kW

Engine maximum torque 870 N.m / (1400r / min)

Rated speed 2000 r / min

Meet the Emission Standard II of China

Fuel tank effective volume of 260L

2, power head, vise

The horizontal directional drilling equipment achieve pushing&pulling by rack and pinion. XCMG’s patented power head and vise double floating technology, greatly reducing the operator’s operation difficulty. And the effective protection of the drill pipe thread, make drill pipe life increased by 30%; four motor drive to achieve a large torque rotation and large cylinder fastening and rotation to ensure that the drill shackle flexible and convenient.

3, the hydraulic system

The main hydraulic components (pumps, valves, motors, cylinders) are used international first-class brands with good performance and high reliability;The hydraulic system adopts the multi-pump coordination to complete the whole machine action, and reasonably matches the engine power; the power head rotation and the push-pull two-speed control can improve the construction efficiency. Push-pull two-speed control can improve construction efficiency.

Hydraulic oil tank volume is 230L.

4, the chassis

XZ320D adopts high-quality steel track (with rubber plate), can adapt to different venues,with high reliability; frog-leg structure and large fuel tank support are with good stability characteristics; large torque walking reducer with superior performance makes walking speed reach 2.8km / h.

Track width of 2150 mm

Track width 400mm

Tread 2140 mm

The number of rollers is 2 × 6

Climbing 30%

Walking speed of 2.8km / h

Average ground pressure 63.6kPa

5.mud pump system

XZ320D horizontal directional drilling equipment equipped with Hengyang or Leike 320L / min large flow mud pump, to provide a strong and powerful mud flow. Hengyang or Leike 320L / min high-flow mud pump ensures smooth and safe operating. Mud pump system equipped with manual pressure relief device can effectively avoid the shackle during the phenomenon of mud jet; also available in winter with the construction of mud antifreeze device, mud cleaning devices and slurry valve to improve the construction of the host convenience.

Maximum slurry flow 320L / min

Maximum pressure of mud 80bar

6, the console, the cab (optional), drill pipe handling equipment (optional), anchoring device (optional)

The operator’s comfort and the rational layout of the instrument are fully considered during the construction process. The cab and the air-conditioner can reduce the labor intensity and improve the work efficiency. Semi-automatic auxiliary drill pipe handling equipment or automatic drill pipe handling equipment selection can improve work efficiency and reduce labor intensity. Fully automatic drill rod handling device can be equipped with 27 ¢ 73 monolithic drill pipe. Automatic anchoring device matching, improve the degree of automation, reduce labor intensity.

Cab size 1350 × 850 × 1550mm

7.Drilling pipe,drilling accessories(option) specification

| Name | Type | style | Size | Remark |

| Drilling pipe | Intergral | ¢73mm×3m | 73 | |

| Welding type | ||||

| Drilling accessories | Back reamer | BARREL | ¢300mm | XCMG |

| ¢400mm | ||||

| ¢500mm | ||||

| ¢600mm | ||||

| ¢700mm | ||||

| ¢800mm | ||||

| ¢900mm | ||||

| Name | Type | Style | Size | remark |

| Drill accessories | Back reamer | FLUTED | ¢300mm | XCMG |

| ¢400mm | ||||

| ¢500mm | ||||

| ¢600mm | ||||

| ¢700mm | ||||

| ¢800mm | ||||

| ¢900mm | ||||

| Accessories | PILOT DRILLING | 73 | ||

| start rod | 73 | |||

| PILOT BOARD | 73 | |||

| torque sleeve | 73 | |||

| left-hand nut | 73 | |||

| male pull head | 73 | |||

| Female pull head | 73 | |||

| swivel | 32T | |||

| PUP JOINTS | 73 | |||

| Slurry system | slurry mixing system | 2M3 | Shanghai | |

| 3M3 | ||||

| Device | Guidance | F1 Falcon | DCI | |

| Falcon | ||||

| F5 | ||||

| Jindi | ||||

| Jindi 350 | ||||

| Jindi 600 | ||||

| Detector | 8000 | UK Radio | ||

Three. Main parameter

| Item | Spe | |

| Engine | Manufacturer | Cummins |

| Model | 6BTAA5.9-C205 | |

| Rated power | 153 kW / 2000 r/min | |

| Power head push and pull | Type | Rack&Pinion |

| Maximum drag force / feed force | 320/320 kN | |

| power head rotation | Type | Four-motor drive |

| Power head max torque | 12000 N·m | |

| Power head rotation | 0~125r/min | |

| Drilling pipe | Diameter | φ73 mm |

| Length(single unit) | 3m | |

| Adjustment angle | 10~20° | |

| Walking drive | Type | Self walking steel track |

| walking speed | 2.8km/h | |

| Mud pump | type | hydraulic drive 320L/min |

Four.Main parts supplier

| Name | Manufacturer |

| Engine | Cummins |

| Main pump | Tianjin PERMCO |

| Auxiliary pump | Tianjin PERMCO |

| Rotation,Push&pull motor | EATON |

| Push&pull reducer | XCMG |

| Track | Quanzhou Juli |

| Walking reducer | Eaton/Dagang INI |

Five. Transporation

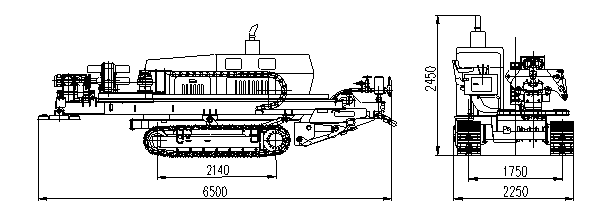

Overall size 6500×2250×2450 mm

Operating weight 10.5T

If cabin,self anchoring,self pipe loading system chosen

Overall size 6800×2280×2450 mm

Operating weight 11.5T

Six.Documents with machine

XZ320D packing documents

Product certification

Instruction Manual

Product spare parts Atlas

ENGINE INSTRUCTION MANUAL

Engine warranty card

Mud pump instruction manual

Packing list (including wearing parts and spare parts list, vehicle tools list, transport parts list)

Seven.XZX320D Horizontal directional drilling equipment main machine equipping explanation

| Name. | Optional function | XZ320D standard | Option |

| Engine | 6BTAA5.9-C205 | YES | |

| Cold start | YES | ||

| Anchoring system | Simple anchoring | YES | |

| Single self anchoring | NO | YES | |

| Double self anchoring | NO | YES | |

| Mud pump system | Mud anti frozen | NO | YES |

| Mud cleaning | NO | YES | |

| Pipe loading system | Half auto pipe loading system | NO | YES |

| Full auto pipe loading system | NO | YES | |

| Cabin | Simple canopy | NO | YES |

| Cabin(coll&warm) | NO | YES |

Note: the product with technical progress will continue to improve, the difference will be in when ordering.

WARRANTY TERM

Wuhan Yichao Technology Equipment Co., Ltd.(Supplier) offers the following limited warranty on Horizontal Directional drilling machine which measure up to the (customer name) in (Territory). The warranty system executes according to the ISO9001 standard.

Our company warranty obligation of the wheel loader are as followings.

INCLUSIONS – ITEMS COVERED BY WARRANTY

(a) The warranty period of the products is one year, which begins from the day the products are received by customer or one month after products leave China port. During this valid period, we will supply warranty parts caused by quality problem during the warranty period. Users will buy the spare parts caused by unsuitable using method.

(b) This warranty covers defects in materials or workmanship only.

(c) The engine and gearbox, transmission are included in the warranty parts. If the defect or failure can be repaired by replacing a parts of the assembly, the dealer/User have no excuse to ask for replacing the whole assembly.

(d)The warranty period of Air Conditioning system, battery, electrical component(excluding bulk),start motor, generator, tyres, rubber seals, hydraulic pipes is 6 months or 1200 hours only(Take standard of the one expiring firstly)

(e) In order to do the after-sale service well, we will warranty to deliver technical information of wheel loaders and attached implements required by users.

EXCLUSIONS – ITEMS NOT COVERED BY WARRANTY

Failure to adhere to and/or comply with operation manual instructions will void all associated warranty obligations.

(b) The damage occurs in the transportation other than in the agreement transportation distance.

(c) Artificial damages. Any repairs or replacements required as a result of misuse, negligence, and abnormal or insufficient care.

(d) Damage caused by the force majeure.

(e) Parts that easy to be damaged.

(e) This warranty does not cover:

- Pickup or delivery of the equipment

- Rental of replacement equipment during the repair period

- Products which have been declared a total loss and subsequently salvaged

- Labor charges

- Freight charges for returned parts

- Travel time or mileage

- Local transport cost in Territory

Consignation of parts

The defect or failure parts have to be sent back to supplier if any warranty confirm firstly,the supplier then send replacing parts to dealer at suppiler’s cost in proper transport methord.

Users Responsibility

(a) It is the users’ responsibility to maintain the equipment in accordance with the instructions provided in the Operator’s Manual. We recommend that you keep records and receipts; you may be asked to prove that the maintenance instructions have been followed.

(b) It is also your responsibility to operate the equipment in a safe manner, and for the use for which was designed. If a defect in materials or workmanship occurs, it is your responsibility to cease operating the equipment until repairs are made. Damage, which occurs from continued operation, may not be covered by this warranty.

Quality question that has not involved in the above provision should be consulted by mutual agreement.